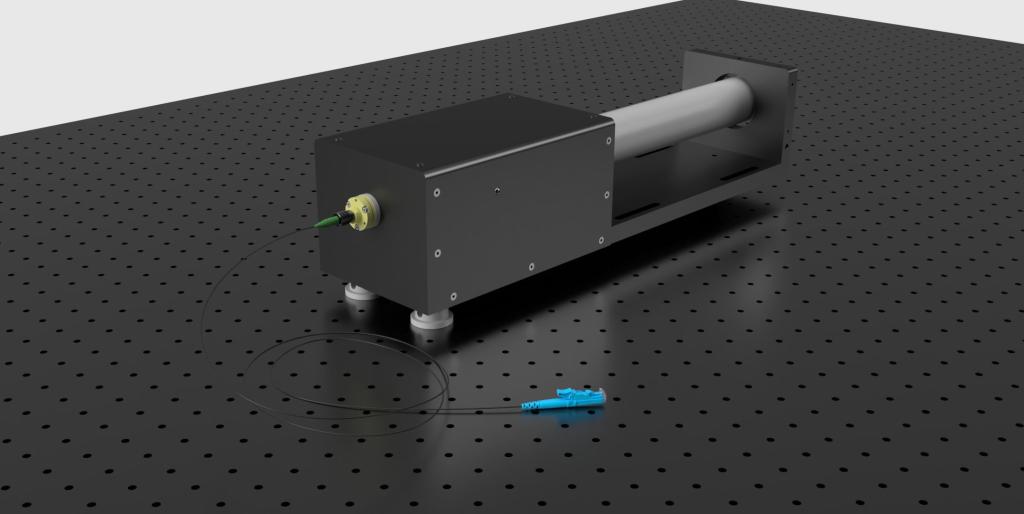

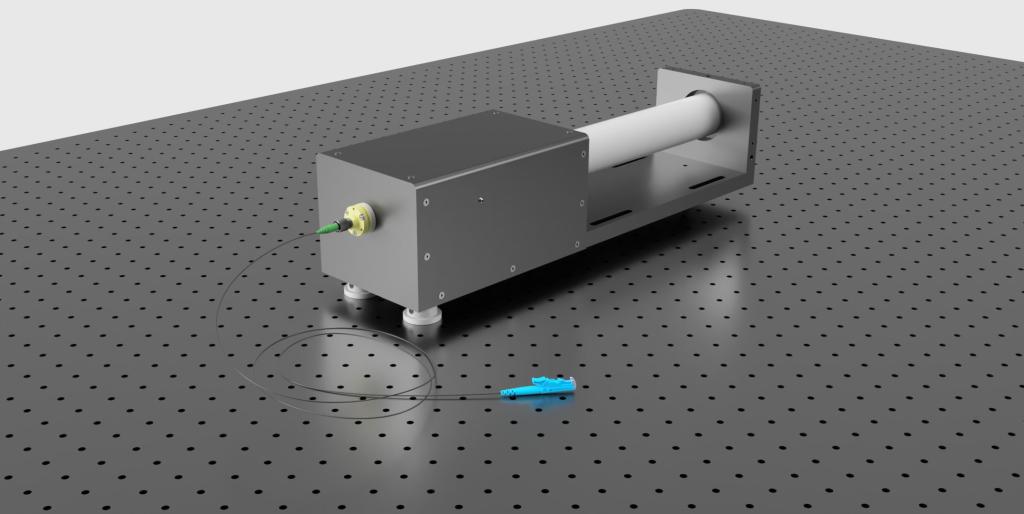

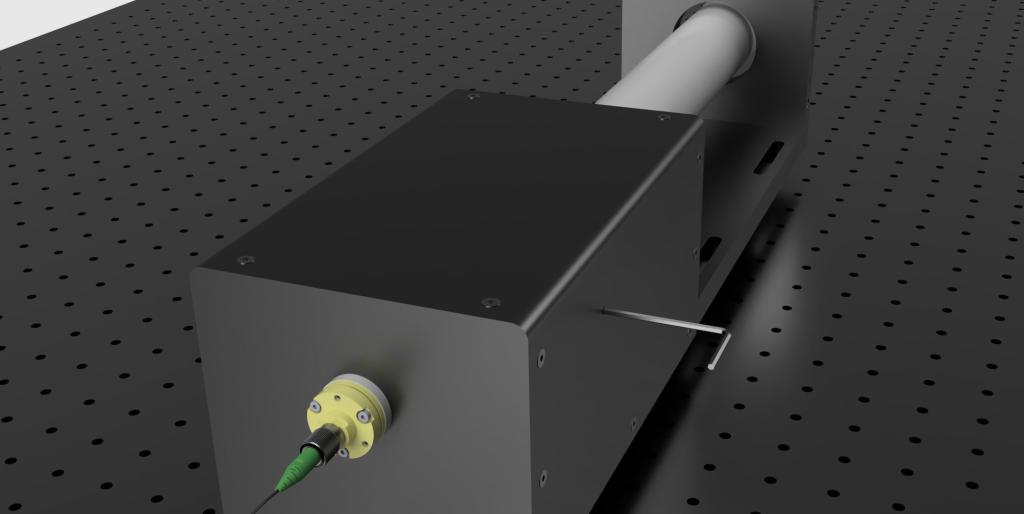

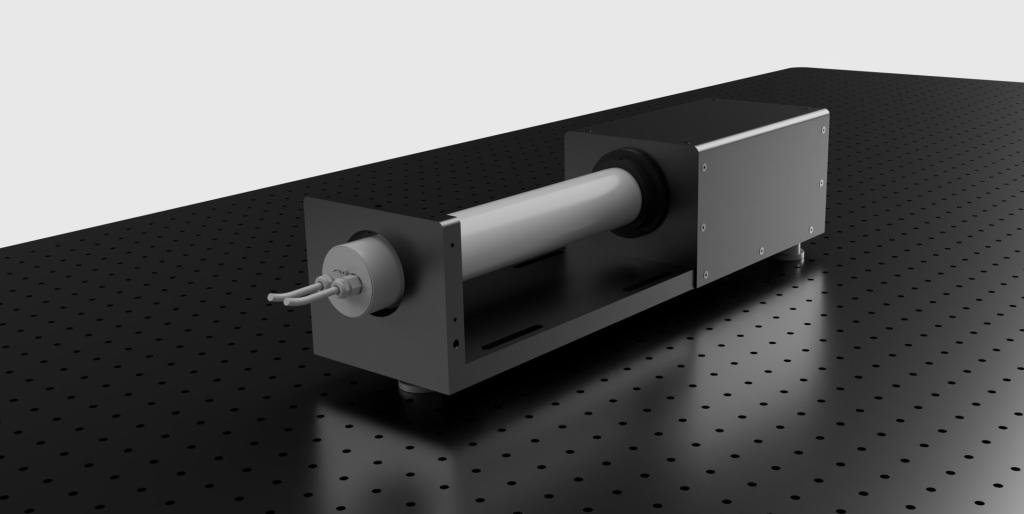

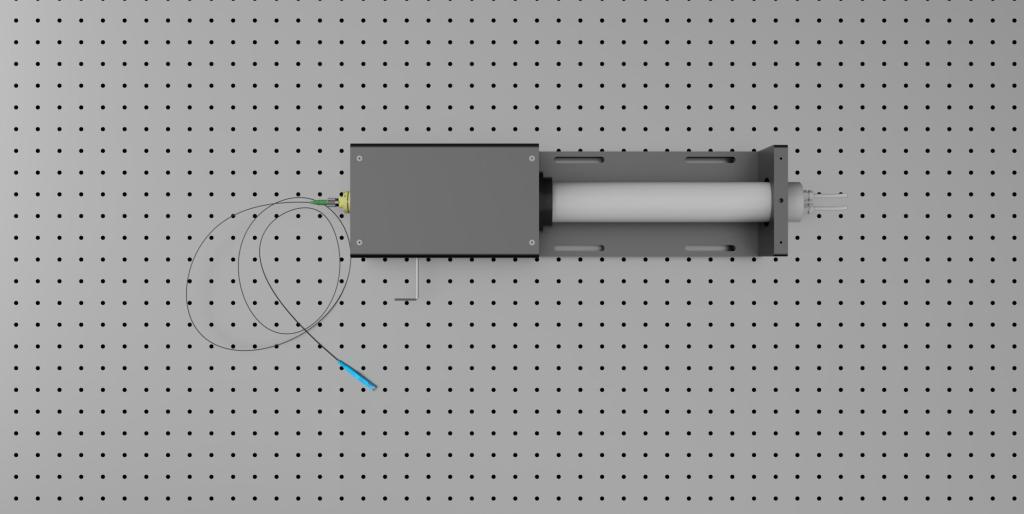

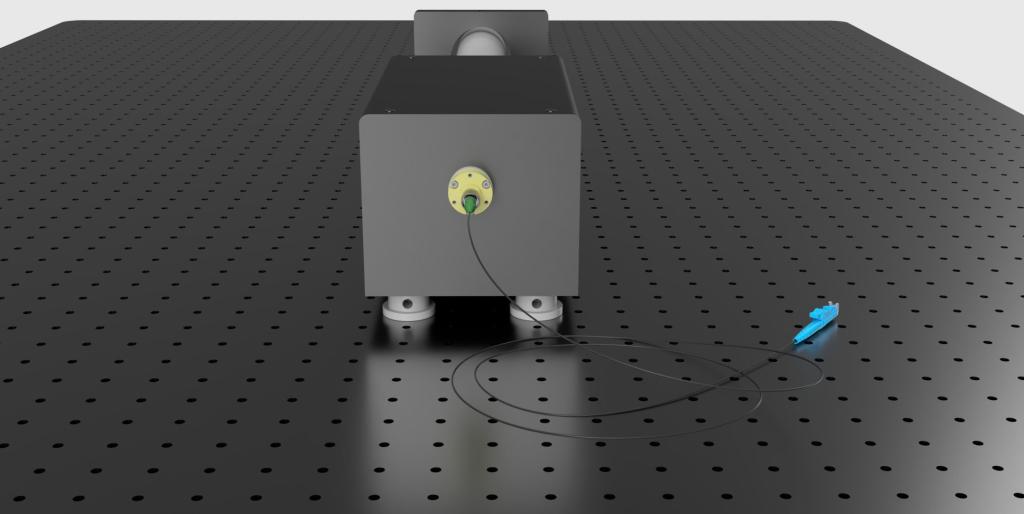

We chose a helium-neon laser from the SL-04 series from our supplier SIOS as the source. Using a series of optical elements, we guided the laser into a polarization-maintaining (PM) fiber with an FC/APC connector on the collimator side and an E2000 connector at the output. Since this is a non-standard combination of connectors, we had to have the fiber custom-made. The APC fiber ends, together with an optical isolator, protect the laser from back reflections. A half-wave plate is also placed in the beam path to allow fine tuning of the laser polarization at the output beyond what would be possible with simple mechanical alignment of the components.

We designed and had an aluminum mounting profile and cover manufactured for the entire assembly, ensuring that the entire module is dust-free from the laser tube output to the fiber connection. Due to the requirement for a high polarization ratio (PER > 30 dB), it is possible to fine-tune the rotation of the half-wave plate from outside the cover. In addition to assembling the module, the process also included testing its mechanical stability and the effect of tube heating on the connected power. We were thus able to provide the customer not only with the module itself, but also with our experience in using it.

Device parameters

- Single-mode output beam with a wavelength of 632.8 nm.

- Option of pure frequency stabilization or combined frequency and amplitude stabilization.

- Polarization extinction ratio (PER) of the output beam > 30 dB with the option of fine tuning using a half-wave plate.

- Output beam power in fiber > 1.1 mW

- Output: optical fiber with E2000 connector.