Lasers provide a more cost-effective and flexible solution for marking medical products and devices. Manufacturers of many types of medical instruments and products use lasers for their product marking needs - they have proven to be flexible, fast and reliable machines that produce markings that meet the most stringent healthcare requirements.

Why do we need marking at all?

Virtually all medical devices and single-use products today must be labeled in some way, either directly or on the sealed packaging. Sometimes this is to meet strict government safety regulations, as in the case of the unique device identifier (UDI) that must be permanently marked on any multi-use device, such as forceps. Sometimes this is so that a batch of disposables can be tracked all the way from manufacture to actual use. Sometimes it is for functional markings such as on epi-pens or to create length markings on intravenous devices. And sometimes it is needed for 'high value' products where there is a risk of counterfeit uncertified products entering the supply chain at some point.

Why is laser marking the best solution in many applications?

Laser marking has quickly become prevalent in many medical device marking applications (and also in many medical disposables). This is because laser marking provides an unbeatable combination of advantages and benefits. For example, laser marking is contamination-free - it uses no inks or other consumables that remain on the product. In addition, the entire marking process takes place without the product touching the machine. As a result, its implementation is usually more cost-effective than non-laser methods. It is also flexible thanks to software control, so anything from simple letters and numbers to complex symbols, graphics, logos and bar or QR codes can be easily created. Just as importantly, the laser creates a permanent mark that cannot be peeled off like a label or removed with solvents like ink. The use of laser marking is so widespread because virtually any metal, plastic or other material used in healthcare can be marked using the right type of laser.

Variety is the spice of life

With a wide variety of metal and plastic parts, a wide variety of packaging types, and batch sizes ranging from units to tens of thousands of pieces, it is simply not possible for a single type of laser machine or even a single type of laser process to meet all marking needs. That's why Coherent offers several different optimized marking solutions, ranging from laser marking subsystems for simple and demanding applications to fully automated systems (machines), with fully unattended operation. Here we take a look at a few of the most commonly used methods.

Ultraviolet (UV) marking of plastics

Plastic medical products, such as catheters and intubation devices, can be laser marked directly or enclosed in laser-marked packaging, or both. Ultraviolet lasers are often used here because they can create a mark on many plastic materials - the most common marking is black on white. Marking can be done without engraving the surface, which could otherwise cause irritation to the patient or act as sites for host contamination. The most common type of UV laser is the nanosecond DPSS laser - for example, the PowerLine E QT series laser sources, which are available in several of our marking machines.

Figure 1: Ultraviolet lasers can mark inside colorless plastics without affecting their outer surface, which is particularly useful for medical disposables.

Marking of metal tubular devices

Medical devices come in a variety of shapes and sizes, but many are tubular in shape. Coherent therefore manufactures a fully automated laser marking machine designed specifically for this application, called the AutoTube Marker. The operator inserts a batch of parts into an input tray and scans a data code. The machine then takes control and not only rotates and marks the parts as required, but also checks the marked parts against user-defined rules and sorts them OK/NOK. Just as importantly, the machine automatically produces a full data log, including taking a photo for product tracking and certification purposes. As the AutoTube Marker is optimised for metal equipment, it comes with a choice of a traditional infrared laser or an ultra-short pulse (USP) laser from our Rapid range, which enables high contrast laser marking.

High contrast black laser marking

In laser black marking, the USP laser causes the metal surface to nanostructure, which then captures the light; the marked surface may appear completely black, but without any chemical changes or oxidation. Black marking is great for both aluminum and stainless steel. And steel remains corrosion resistant even after repeated sterilization (steam.) You can read more about laser black marking here.

3D marking

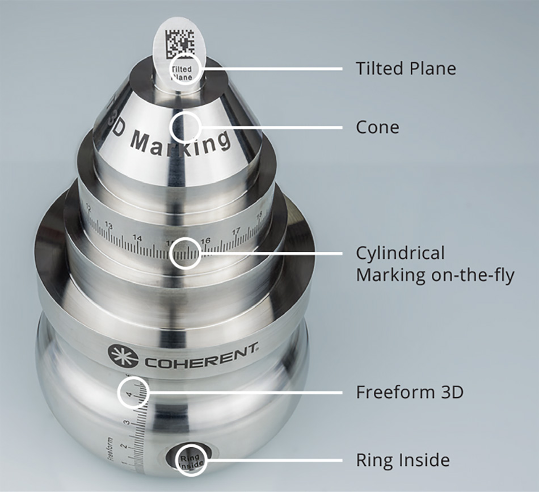

Many medical devices are tubular or flat, but some are neither; they may have angled, curved, or unusually shaped surfaces to mark on. For many years, the only way to laser mark these surfaces was to resort to robotics or five-axis CNC machines. Instead, Coherent offers a "smart" 3D marking solution that combines extremely dynamic 3D focusing technology with new 3D machine vision and powerful marking software called Visual Laser Marker (VLM). This visualizes the relative position of the laser and the workpiece and provides an accurate view of the marked part. The VLM software also accepts CAD files with the workpiece design, supports various types of 2D → 3D mapping and automatically adapts the marking process to free surfaces.

Examples of 3D marking

Figure 2: Several examples of different types of 3D marking, in this case performed with a USP black laser marker.

Source: www.coherent.com