The remote-controlled Coherent SmartWeld+ laser welding tool shapes welds and profiles with maximum precision and optimised heat input.

Industrial welding applications, such as e-mobility manufacturing, are driving an increased need for welding difficult-to-weld metals such as copper and aluminum or joining dissimilar materials. The Coherent SmartWeld+ precision remote-controlled welding head, introduced in 2019, provides the precise energy distribution and weld depth control necessary to successfully create these types of welds.

The new PH20 SmartWeld+ welding head extends the range of this proven technology to lasers up to 5 kW. This makes it compatible with a wider selection of single-mode standard fiber lasers and adjustable ring mode (ARM) fiber lasers, including the Coherent HighLight FL CSM ARM, HighLight FL CSM and PowerLine FL 1000/1500 lasers. The result is the ability to weld thin and thick materials with unmatched accuracy and high speed.

What's so smart about SmartWeld+ laser technology?

The SmartWeld+ laser head achieves this combination of speed and accuracy by combining solid optics for beam transmission with a highly dynamic galvanometric scanning module (speeds up to 4 kHz). This is controlled by sophisticated software to create a variety of pre-programmed scan patterns. These "smart" patterns go far beyond traditional beam oscillation and include spirals, ellipses and other complex shapes. In addition to increased performance, software enhancements in the PH20 SmartWeld+ system allow the beam motion (pattern orientation, size and frequency of oscillation) to dynamically adjust to compensate for individual workpiece variations measured by the vision system. In combination with the ARM laser, this beam control can be synchronized with high-speed independent power modulation of the center and circular beam. This provides an unprecedented level of spatial and temporal control of how the laser power is applied. All of this results in more consistent weld quality and seam dimensions while alleviating part facing requirements. And with an expanded 50 x 50 mm working area, the latest SmartWeld+ can sometimes eliminate gantry movement to achieve even higher speeds.

Better welding

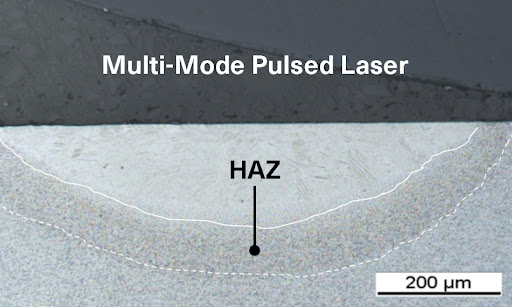

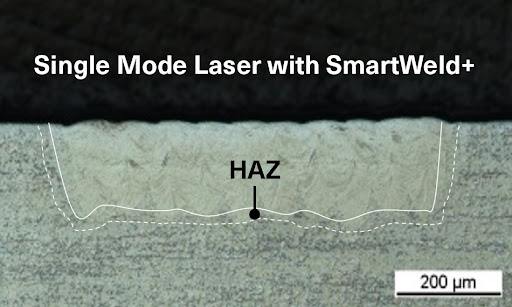

The results demonstrate the ability of the SmartWeld+ laser system to precisely control the dimensions and shape of the weld, as well as reduce heat input. The two photos compare welds from a traditional multi-mode laser (approximate focus point size 800 µm) with the much lower power of a single-mode laser (approximate focus point size 30 µm) controlled by SmartWeld+.

A traditional multi-mode pulsed laser produces a weld with uneven depth and a relatively large heat-affected zone, while SmartWeld+ in conjunction with a single-mode fiber laser produces a weld with uniform depth and strength and a minimal heat-affected zone.

The SmartWeld+ system produces a weld cross-section that is more rectangular and 40% larger than the traditional approach. At the same time, it creates a much smaller heat-affected zone due to reduced overall energy input. The result is minimized thermal stress and crack formation and an overall increase in weld strength.

In addition, the smaller beam focus achieved with a single-mode source increases energy concentration. This improves process stability for highly reflective materials - such as copper or aluminum - that are typically difficult to weld, especially with infrared lasers.

Learn more about SmartWeld+laser head technology .

Source.