Call

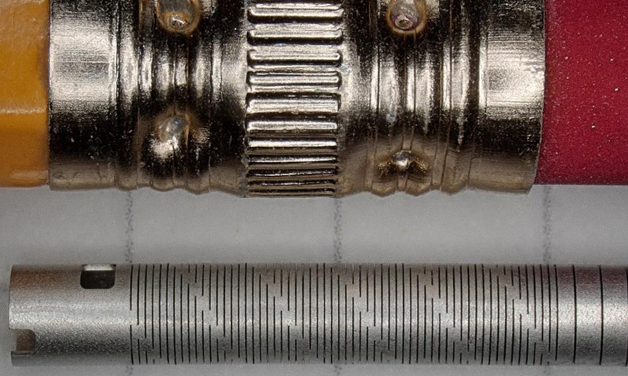

Motion Dynamics (Fruitport, MI) is a contract manufacturer specializing in custom micro springs, medical coils and wire components. It has a hard-earned reputation for solving challenging problems in the shortest amount of time, no matter how difficult or seemingly impossible. They have particular expertise in designing and manufacturing complex assemblies for neurovascular procedures - for applications such as steerable catheter devices, including "pull-wire" assemblies.

President Chris Witham states, "The company's medical device business is based on a highly focused business model in neurovascular products where we can offer differentiated results in terms of design, execution and service. We need fast, versatile and easy-to-use laser cutting machines to create components for high-value 'difficult' assemblies." He explains that cutting flexibility and ease of use are critical machine requirements for Motion Dynamics, as these components are quite diverse in terms of size, shape and material, with only small to medium batches in most cases.

"The StarCut Tube Hybrid allows us to optimize the cost of cutting each component, even individual cuts within a single component."

- Chris Witham, president of Motion Dynamics, Fruitport, Mich.

Solutions

The company already has several years of experience using Coherent's StarCut Tube machine. Until recently, the machine was available with a choice of either an ultra-short pulse (USP) laser with femtosecond pulsing or a more traditional fiber laser with much slower pulsing. Witham explains that when purchasing the first model, they opted for the USP laser because it provides excellent edge quality and minimises cut-through, which is critical for many of their components. In fact, the USP laser typically eliminates the need for post-machining of parts. He adds that "there isn't a material we use that can't be cut with the USP laser yet, including the tiny gold components used as radio-optical markers in some of our products."

When market growth meant that even two 40-hour shifts a week weren't enough to keep up with the demand for their neurovascular assemblies, they decided to purchase another StarCut Tube machine. However, some of the components used by Motion Dynamics are made of thicker material (up to 50 hundredths of a mm) and could be cut more economically using the higher processing speed of the fibre laser.

The optimal solution was the latest StarCut Tube Hybrid machine, which incorporates both femtosecond and fiber laser, all integrated in the same compact platform with the same user-friendly graphical interface.

Result

Witham says the flexibility of the new machine is proving to be a major advantage: "We can now choose which process - whether using the USP laser or the fibre laser followed by machining the product - is the most economically viable for each part. This machine even allows us to explore the possibility of mixed processing of the same part, especially when it comes to larger diameters and wall thicknesses: specifically, fast cutting with the fibre laser followed by fine cutting with the femtosecond laser." He expects the USP laser to remain their first choice in many cases, as most of their laser cutting involves stainless steel tubing with wall thicknesses between 10 and 15 hundredths of a mm.

Source: www.coherent.com