Plastics are a ubiquitous part of today's world, with global production exceeding 380 million tonnes per year. A significant part of this production is black plastics, which are popular for their aesthetic and functional properties, especially in high-demand sectors such as automotive manufacturing, packaging and chassis for electronics or food packaging.

Currently, the recycling rate of black plastics is still very low, mainly due to problems associated with traditional sorting technologies. Near-infrared (NIR) imagers, which are commonly used for plastics sorting, have difficulty detecting black plastics because their soot pigmentation absorbs light rather than reflecting it. As a result, black plastics are often misidentified, leading to incorrect sorting, reduced recycling rates and increased landfill.

Stricter regulations are being adopted in the regions, requiring manufacturers to include a certain percentage of recycled plastics in new products. Effective methods of sorting black plastics are needed to meet these targets.

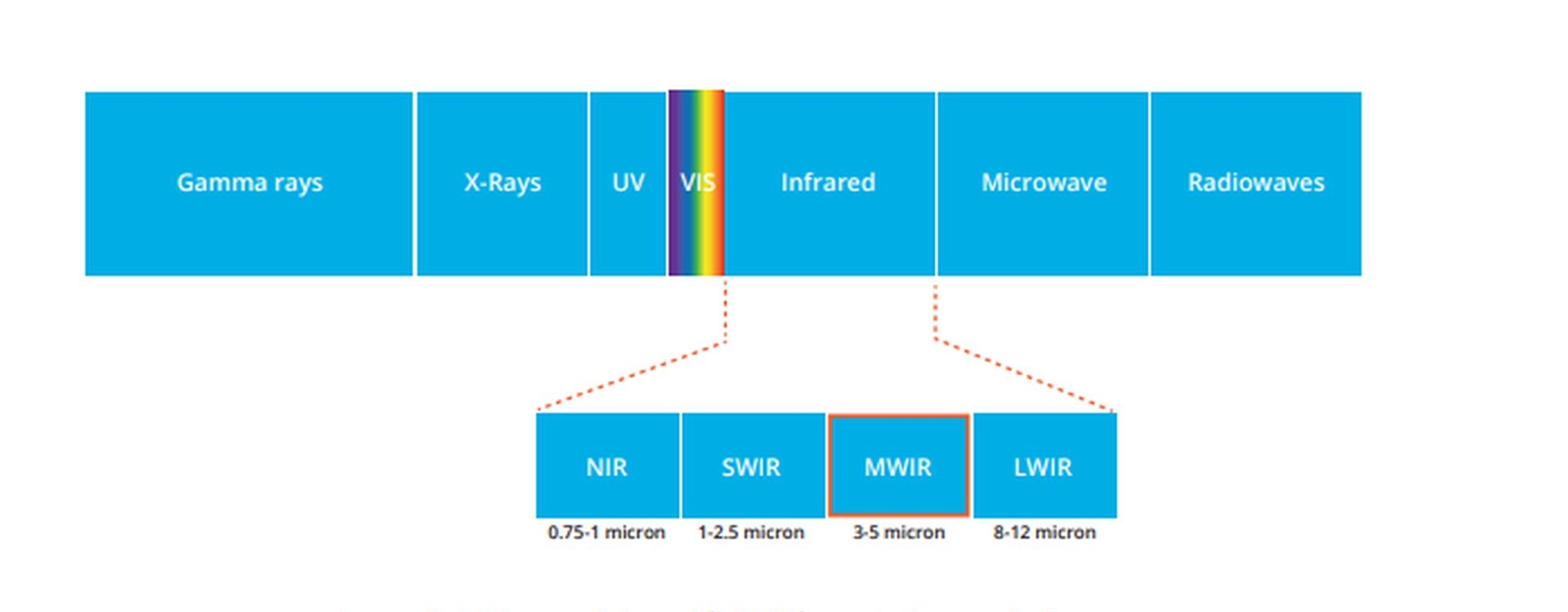

Hyperspectral imaging (HSI) in the mid-wavelength infrared (MWIR) region offers a solution that overcomes the limitations of near-infrared (NIR)-based systems and significantly improves the accuracy and efficiency of black plastic sorting. Optical black plastic sorting offers an efficient solution that enables customers to accurately sort black plastics and free them from gravity-based sorting methods that rely on large amounts of water, salt and other resources that contribute to environmental pollution.

This application note demonstrates the capabilities of MWIR HSI - specifically the Specim FX50 camera - and how it can be integrated into industrial sorting systems to address this challenge. It aims to provide a comprehensive overview for industrial decision makers and technical experts seeking to improve their sorting processes and achieve greater efficiency in material recovery, particularly in relation to the sorting of black plastics.

An introduction to hyperspectral imaging (HSI) and its benefits in material sorting

HSI is an advanced technology that scans materials and captures and analyses a wide spectrum of light in many narrow wavelength bands, far beyond what the human eye or conventional cameras can see.

This data forms a unique "spectral fingerprint" of each material, which can be analysed using sophisticated algorithms to identify and distinguish different materials with high accuracy.

HSI makes it possible to distinguish between materials that would otherwise appear similar using other imaging technologies. In addition, HSI supports real-time processing, enabling fast, accurate and automated sorting, making it particularly valuable for industrial sorting.

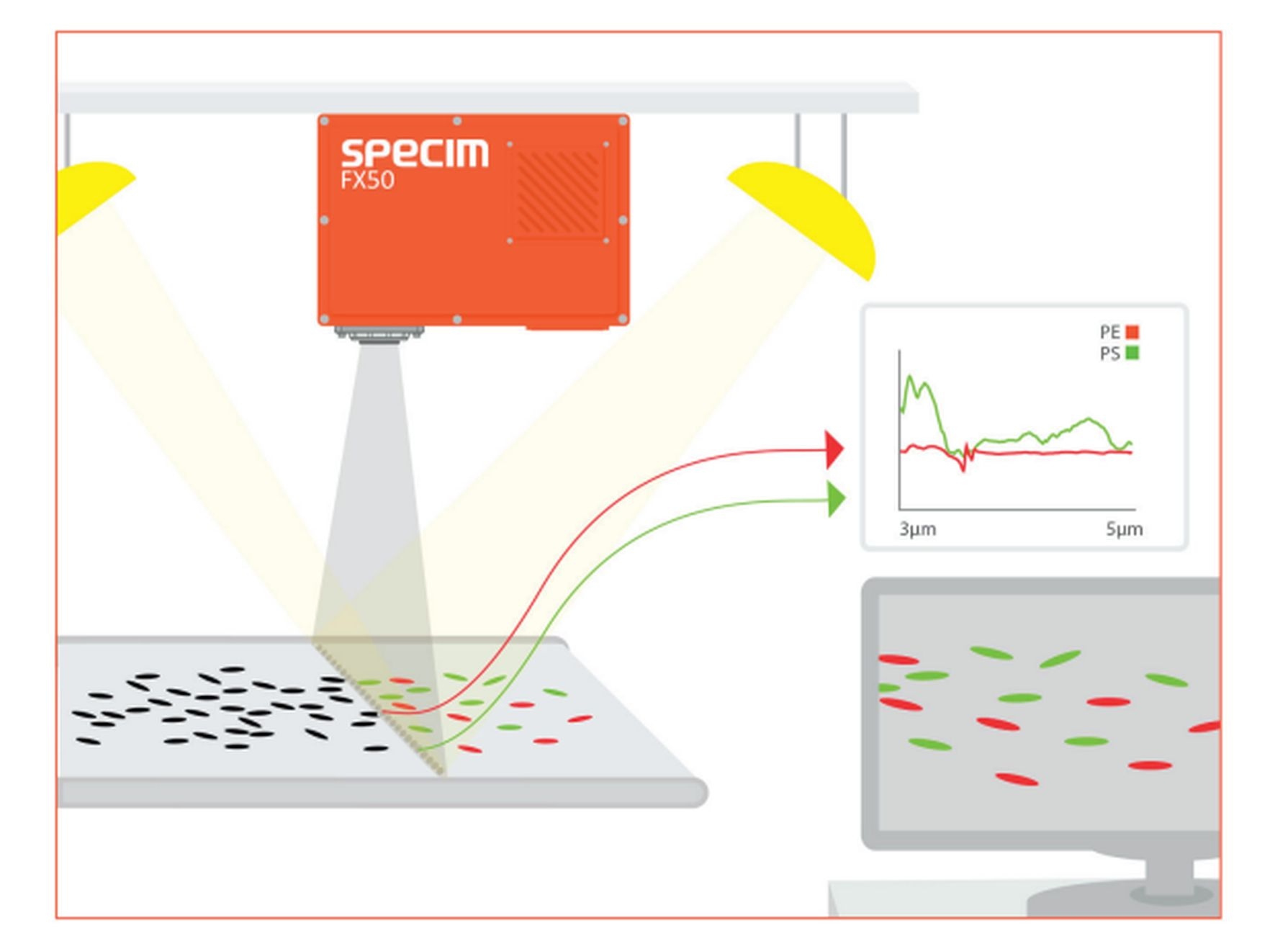

Figure 1: Typical setup for inline resolution of various black plastics using MWIR hyperspectral imaging technology

Overcoming the challenges of sorting black plastics using MWIR HSI

Until recently, no reliable sensor technology existed to sort black plastics for reuse. Traditional near-infrared (NIR) sorting technologies rely on the reflection of infrared light to identify and sort plastics. However, most black plastics are coloured with soot, which absorbs infrared light rather than reflecting it, making it 'invisible' to NIR sensors. This often leads to misidentification or exclusion from the recycling process.

MWIR HSI, however, changes this situation. Whereas near-infrared (NIR) imaging captures spectral information in the range of approximately 0.9 to 2.5 micrometers (µm), MWIR hyperspectral imaging captures detailed spectral information over the entire MWIR wavelength range of 3 to 5 micrometers (µm).

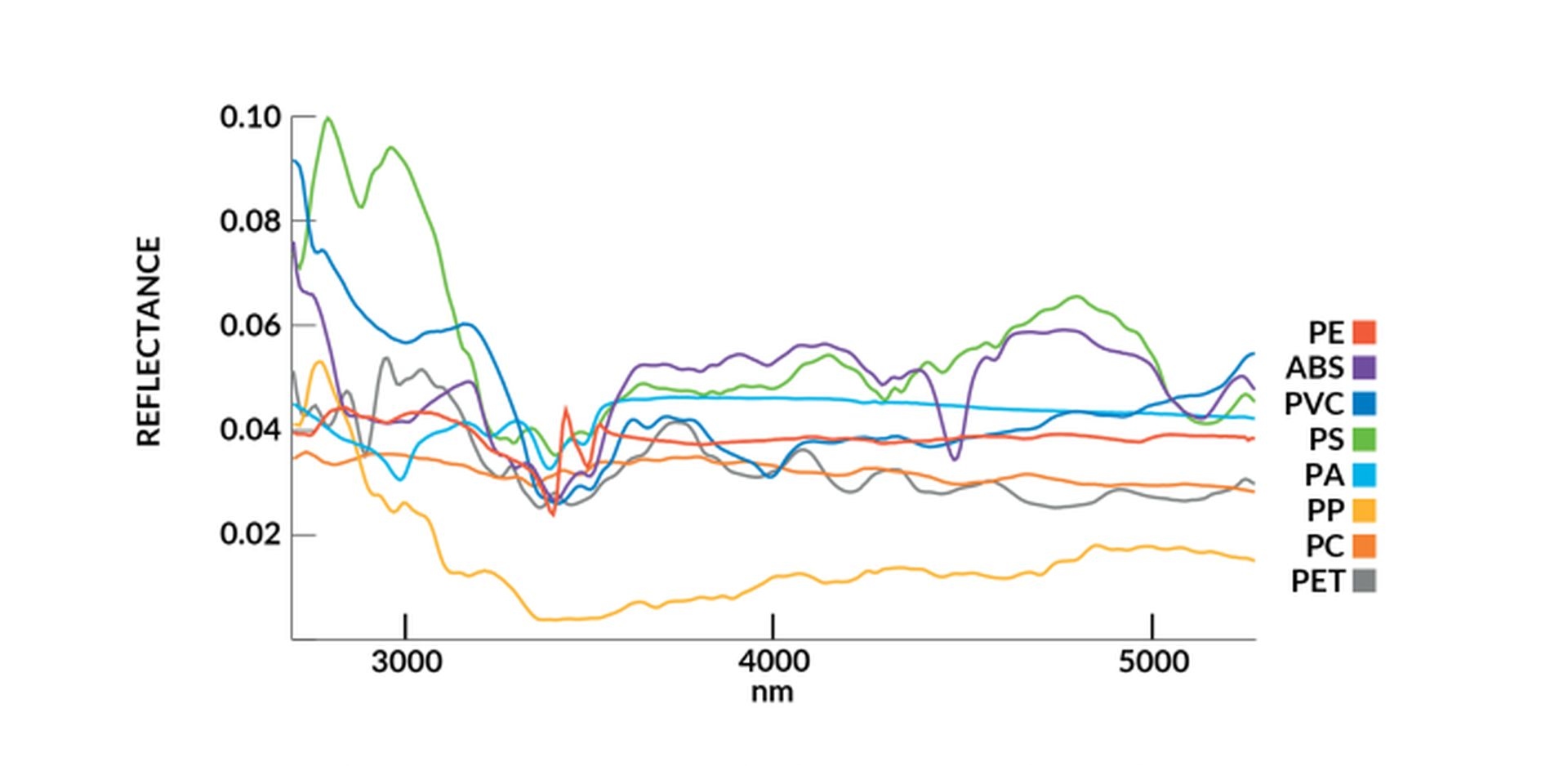

In this range, different plastics exhibit unique spectral properties due to their molecular composition (see Figure 3 below). As a result, when working in the MWIR region, HSI can distinguish between different types of black plastics regardless of their color.

Specim FX50 - a breakthrough in black plastic sorting

The Specim FX50 MWIR solves the problem of "invisible" black plastics by operating in the mid-wave infrared (MWIR) region. It is the first hyperspectral camera on the market that covers the entire MWIR spectral range of 2.7 - 5.3 μm, which is crucial for black plastic sorting. This capability allows it to detect spectral features that traditional NIR cameras simply cannot see.

Specifically designed for industrial sorting applications, the Specim FX50 camera offers the speed, resolution, sensitivity and durability necessary for reliable inline sorting. With its MWIR capabilities, the Specim FX50 can effectively identify black plastics, rubbers and non-black plastic compositions.

Specim FX50 enables fast and reliable sorting:

-

Black plastics

-

Rubber

-

Non-black plastics and rubber

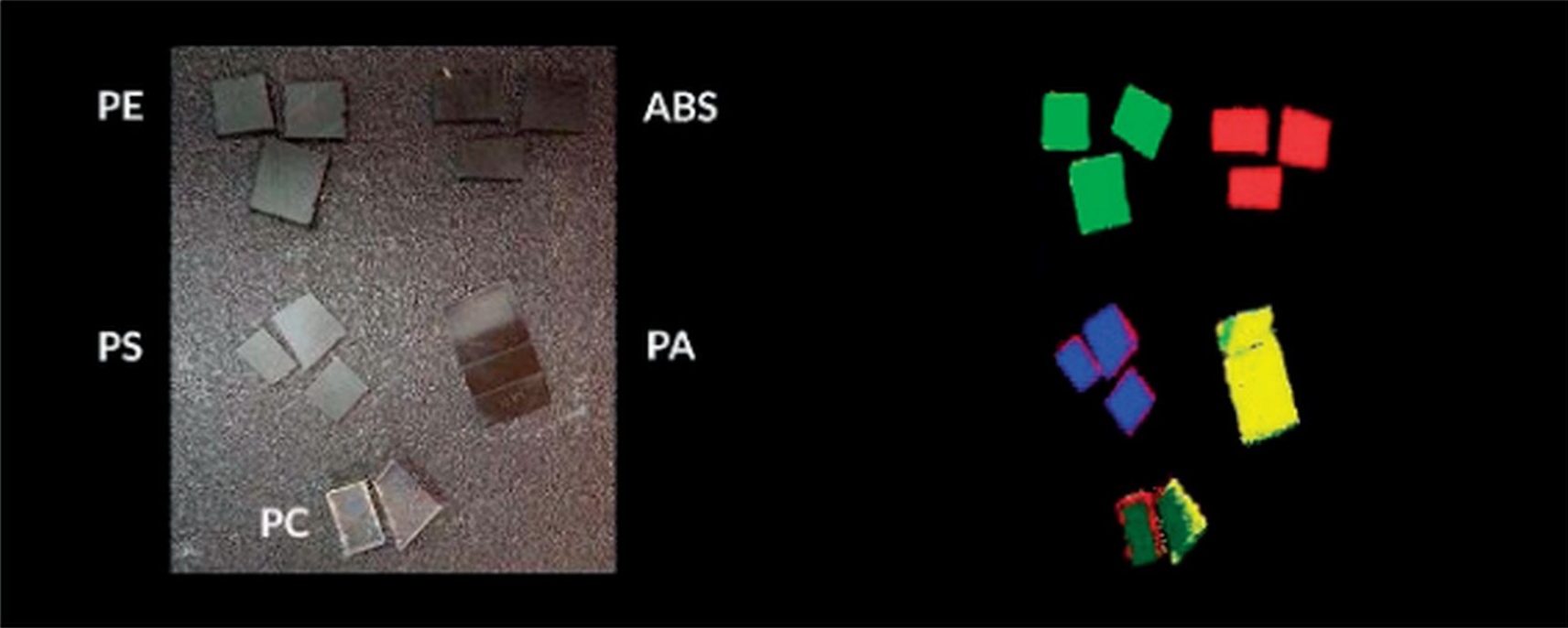

Figure 6: Example of RGB and HSI images of various black plastics measured in the lab with the Specim FX50

The Specim FX50 uses push-broom technology, which is very beneficial in industrial sorting applications. Its fast sensing and detection capabilities enable accurate real-time identification of moving objects on conveyor belts, reducing the costs associated with identification errors. For example, the Specim FX50's fast frame rate and high spatial resolution allow it to sort 300 kg of 2x2 cm plastic flakes per minute on a 1 m wide conveyor belt running at 2 m/s with nearly 99% accuracy.*

The high performance and accuracy make the Specim FX50 a highly competitive choice for the recycling industry where speed, accuracy and cost efficiency are critical.

* Final speed and performance may vary depending on operating conditions and types of plastics being sorted.

Fusion of HSI and X-ray sensor for flame retardant (FR) sorting

Flame retardant (FR) compounds can affect the detection of plastics by altering certain material properties. However, the presence of FRs does not prevent the identification of plastics. Flame retardants may or may not be visible on detection and in most cases are not visible.

The FX50 can detect a variety of plastics, even those containing some flame retardant compounds. While it may not always detect FR itself, this limitation can be mitigated by sensor fusion by combining hyperspectral imaging (HSI) with X-ray technology. While the FX50 sensor accurately identifies plastics, X-ray technology complements it by detecting the presence of flame retardants based on differences in material density. This integrated approach provides a more comprehensive solution for sorting black plastics, especially in industries where flame retardant compounds are increasingly used, such as automotive.

How to integrate FX50 with sorting systems

The Specim FX50 can be integrated into an industrial sorting system in two basic ways: using the SpecimONE platform or via a Software Development Kit (SDK), depending on the customer's needs and resources.

1. Integration with the SpecimONE platform

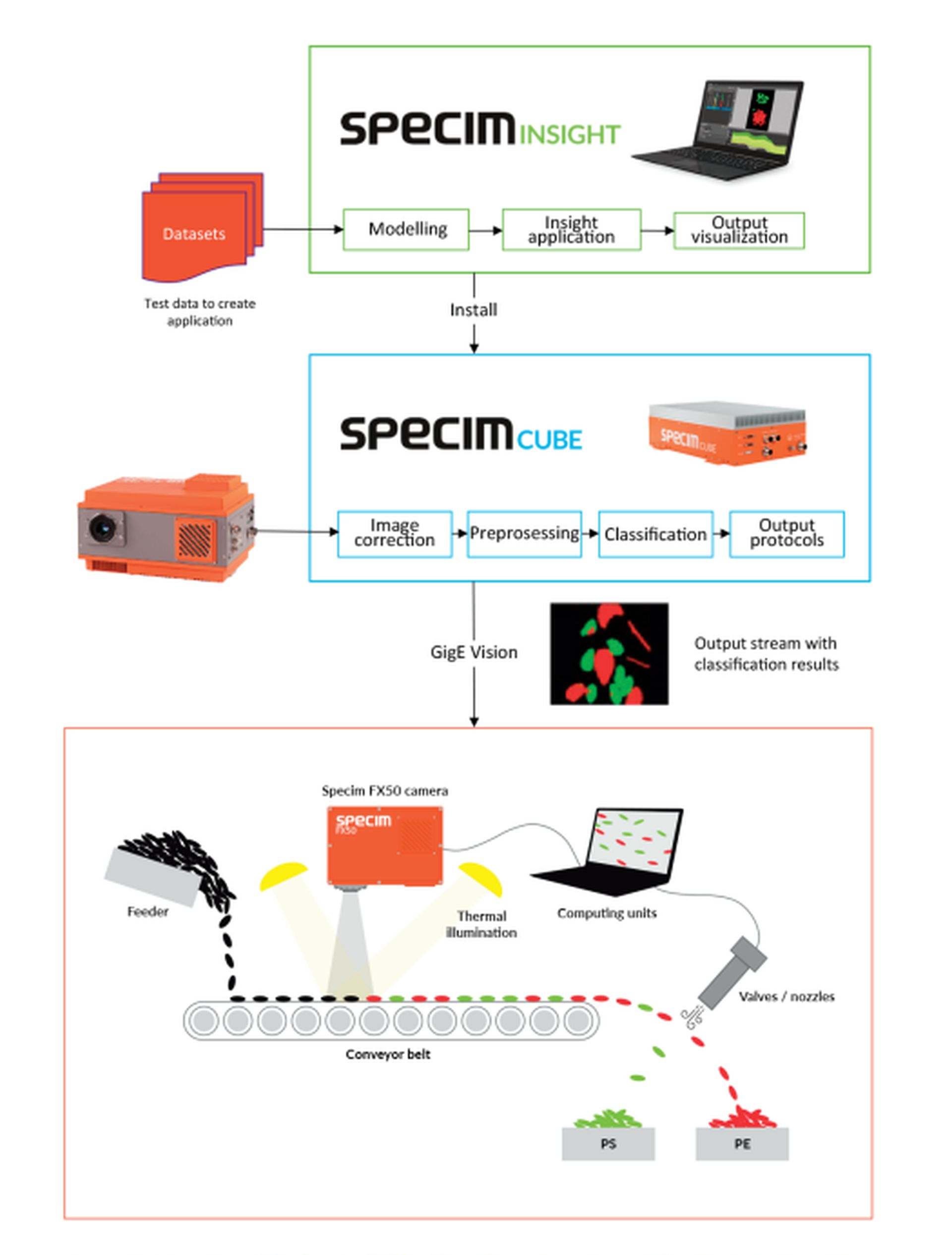

The SpecimONE platform offers a complete solution for integrating the Specim FX50 camera with sorting systems, from data acquisition to real-time processing.

Figure 7: The SpecimONE spectral imaging platform includes the industry-proven Specim FX50 hyperspectral camera, SpecimCUBE processing hardware, and the SpecimINSIGHT HSI data analysis software tool.

Data analysis and classification with SpecimINSIGHT:

SpecimINSIGHT software can be used to analyze spectral data acquired by the FX50 camera. This software allows users to examine the unique spectral signatures of different materials and create classification models based on these data.

Real-time processing using SpecimCUBE:

Once classification models are created using SpecimINSIGHT, they are transferred to the SpecimCUBE real-time processing platform. Designed for high-speed inline processing, SpecimCUBE converts spectral data from Specim FX50 into real-time classification decisions. This platform ensures fast and accurate sorting in demanding industrial environments. SpecimCUBE is compatible with GigE Vision, the global standard for high-speed image data transmission, enabling seamless integration of the Specim FX50 with a wide range of grading machines and industrial automation systems.

2. Integration with SDK (Software Development Kit)

The second option is to integrate the Specim FX50 using an SDK, which offers greater flexibility for customers who prefer to develop their own processing hardware and software. With the SDK, customers are provided with the tools needed to access the raw camera data and develop their own material sorting algorithms. In this approach, the customer is responsible for building the entire processing chain, from data collection to real-time processing, using their own hardware and software interfaces. This option is ideal for users with specific or highly customized requirements and good HSI knowledge.

MROI functions for sorting optimization

The MROI (Multiple Regions of Interest) feature included with the Specim FX50 allows users to select specific portions of spectral data that are most relevant to their application. This means that you can focus the camera's computational power on specific wavelength ranges that are important for identifying specific materials, while ignoring other irrelevant parts of the spectrum.

For example,CO2 interference affects spectral data in the mid-wavelength infrared (MWIR) region, typically around wavelengths of 4.2 to 4.4 micrometers (µm). CO2 strongly absorbs infrared light in this range, which can confuse spectral data when sorting materials such as plastics.

By removing this irrelevant data, the system reduces potential inconsistencies in the analysis and provides a more accurate hyperspectral image. This makes the sorting process more efficient in several ways:

-

Faster processing.

-

Reduced data load: the system processes only relevant data, thus reducing computational memory requirements.

-

Improved robustness: By focusing only on meaningful spectral data, the algorithm is more robust and less prone to errors caused by irrelevant spectral information.

Overall, MROI improves the performance of sorting systems by streamlining data processing and providing more accurate and efficient sorting.

Consistent results across cameras with uniform spectral calibration

Regardless of the integration method, one of the key advantages of the Specim FX50 is its uniform spectral calibration. All Specim FX50 cameras are calibrated to exact specifications at the time of manufacture. This standardized calibration eliminates the need for software adjustments for wavelength variability and ensures consistent spectral data in all units.

This uniform spectral calibration means users can create sorting models with one Specim FX50 camera and transfer them to other FX50 cameras (or any other Specim FX models) without additional recalibration, saving time and ensuring consistent results across systems.

Recommended operating conditions

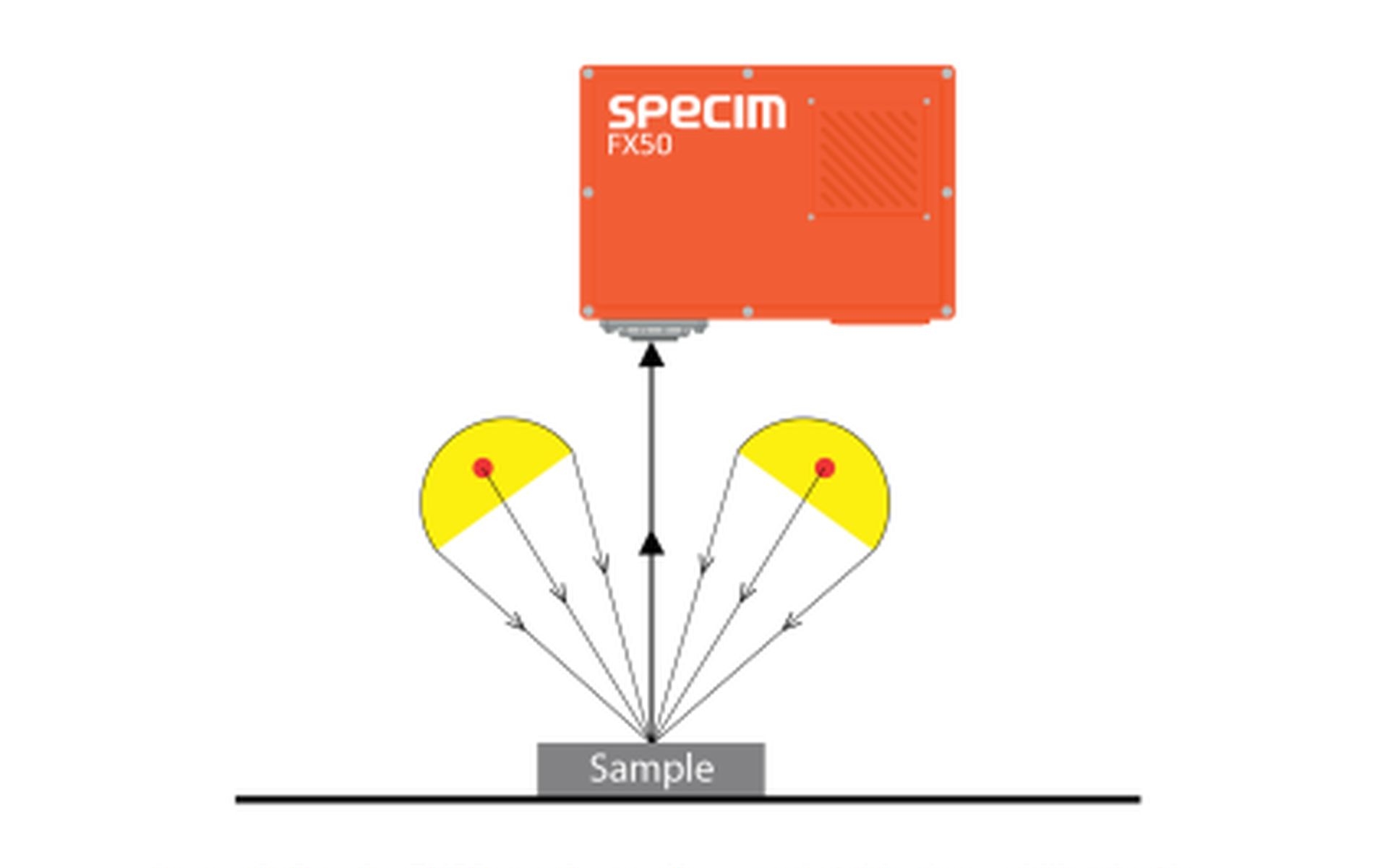

Lighting requirements

Lighting plays a critical role in the performance of the Specim FX50 MWIR hyperspectral camera. The camera requires a strong, uniform and stable source of thermal light. Proper lighting ensures that the spectral properties of materials are clearly visible even at high conveyor speeds. The lighting system must emit light in the MWIR region (3 to 5 micrometers).

Tips for optimizing lighting

-

Typically, a thermal illumination source with a temperature range of 900-1000 kelvin is used to provide sufficient intensity for the camera to capture accurate spectral data.

-

We recommend using a heating element made of alloy, which ensures that the light source will remain durable and stable over a long period of time and provide consistent thermal radiation.

-

Specim offers a variety of lighting options and can also recommend suitable third party solutions based on your specific needs and application setup.

Operating temperature and vibration

Maintaining a stable operating temperature and vibration control are critical to maximizing the performance and life of the Specim FX50. You can optimize the performance and operating life of the FX50 by taking the following measures.

Sensitivity and stabilization of thermal emissions

-

Operating temperature: To ensure stability of camera components, including optics, and to ensure the longest possible lifetime, the ambient operating temperature should be between 5 and 25 °C.

-

Temperature stability: For the most accurate spectral readings, the camera optics should maintain temperature variations within +/- 1 °C, as larger variations may affect the accuracy of material identification.

-

Temperature Stabilized Optics.

-

Advanced Cooling:The FX50 includes an advanced cooling system that maintains optimal sensor temperature, reduces dark noise (interference) and maintains high sensitivity for clear and accurate spectral readings.

-

Temperature stabilized housing: We recommend using a temperature-stabilized housing to protect the camera from temperature fluctuations, dust and dirt. Customers usually design their own covers according to our recommendations, but there are also specialized cover suppliers who can offer customized solutions.

Vibration control

Vibration is a common problem in industrial environments, particularly in conveyor systems used for sorting. Excessive vibration can not only affect the stability of the camera and compromise the accuracy of spectral data, but also shorten the life of the camera over time and therefore needs to be reduced.

To minimize the effects of vibration and extend the operational life of the camera, we recommend mounting the camera separately from the conveyor system. Additionally, the use of vibration dampers on the feet of the instrument can further reduce vibration transmission, which will help protect the camera and ensure consistent data accuracy.

Summary and conclusion

The Specim FX50 hyperspectral camera solves one of the biggest challenges in modern recycling: sorting black plastic. Unlike traditional NIR-based systems, the FX50 camera uses unique spectral signatures in the MWIR region, enabling accurate identification of a variety of plastics - even the most challenging black plastics - and rubbers.

With high-speed processing and nearly 99% sorting accuracy, the Specim FX50 offers a reliable inline solution for industrial sorting. Its design ensures seamless integration into existing systems, optimized for high-performance plants.

By deploying the Specim FX50, industrial plants can significantly increase recycling rates and meet regulatory requirements.

Contact us today to find out more information or for further technical details. Our experts are ready to support you in implementing this advanced technology into your operations.

Source: specim.com