Helping to power our electrified future

Laser welding of copper enables manufacturers to produce stronger, lighter, and more efficient electric vehicles for a sustainable future.

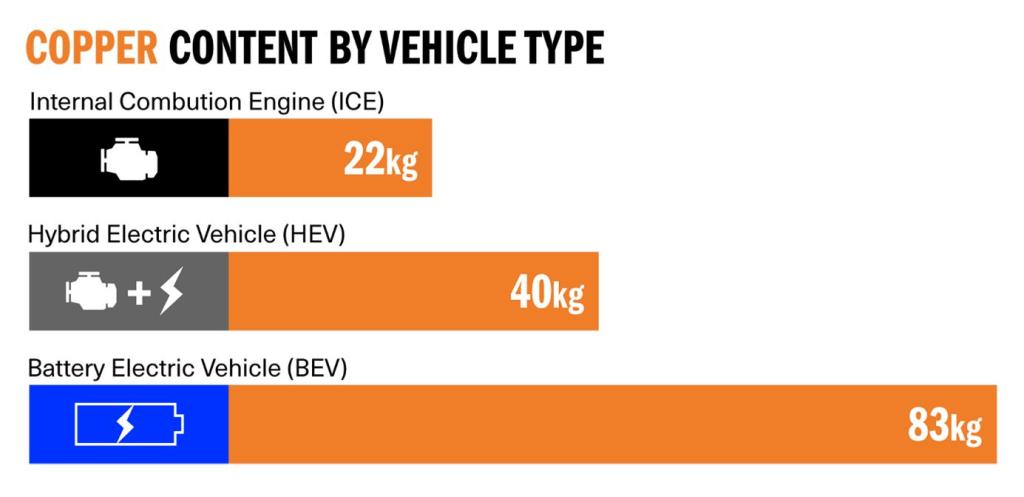

Copper plays a vital role in the automotive industry, whether the fuel source is gasoline, diesel, electricity, fuel cells, or LNG. Demand for copper in vehicles is expected to grow from 3 million tons (MT) in 2023 to 5 MT by 2034. The real driver here is the significant increase in the use of copper for electric vehicle (EV) components as a result of the longer range that consumers demand from EVs, with battery pack capacity increasing at a rate of ~10% per year. Larger batteries, larger converters, and faster charging require greater current capacity, which means that stronger connections with lower resistance are needed.

Laser welding is coming to the fore in the field of joining electric vehicle powertrains

Laser welding, as a contactless and highly automated process, is rapidly becoming the preferred method for assembling key components of electric vehicle powertrains. However, with the development of electromobility, these components require deeper and higher-quality welds with a larger cross-section than has been possible with this technology to date.

Typical applications for electric vehicles

- Converters: Laser welding is widely used in inverters using IGBTs, but especially in inverters using the latest generation of silicon carbide (SiC) MOSFETs, both for electric vehicles and charging stations.

- Battery block busbars: Due to increased performance requirements, thicker copper cross-sections are used in battery packs for electric vehicles and other high-current electrical connections.

Advantages of deep laser welding on copper using ARM FL

The latest ARM FL laser welding system from Coherent offers several advantages for joining thicker copper profiles in electric vehicles:

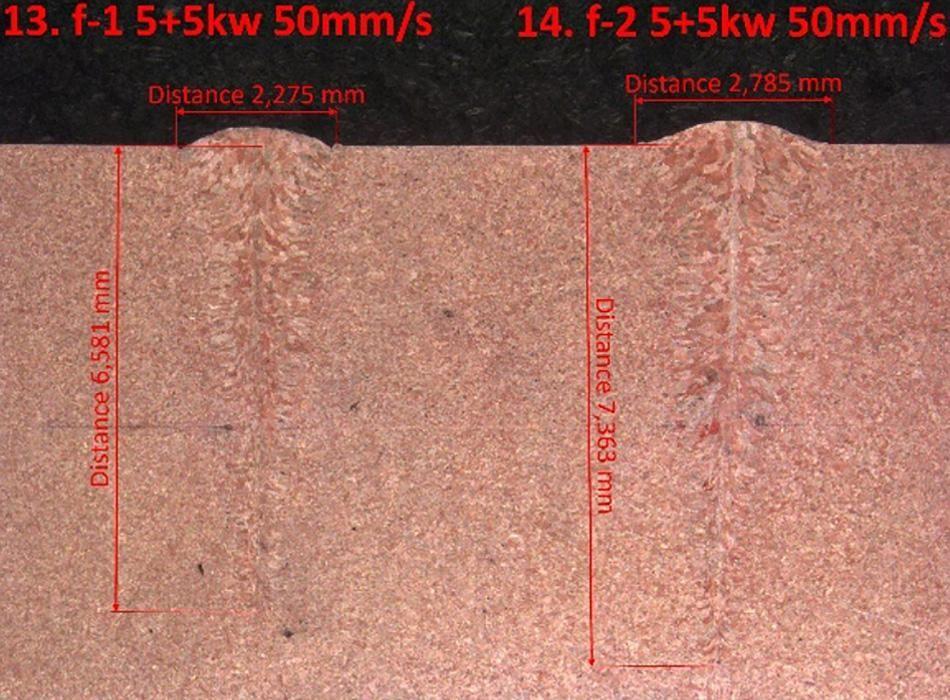

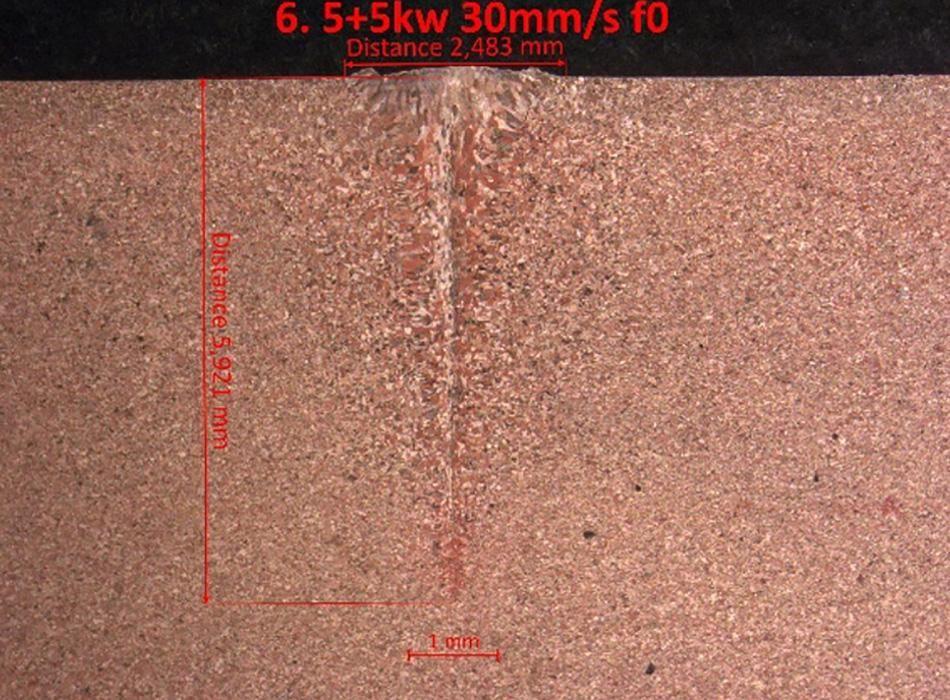

- High-quality deep copper welds with narrow cross-sections: The latest ARM FL fiber laser can now produce welds up to 7 mm deep with excellent electrical performance and minimal porosity and spatter.

- Weight and material reduction: These new deep welds can effectively replace mechanical joining methods, resulting in significant weight and material savings—a crucial factor for electric vehicles.

What's new with the ARM FL 10kW?

The latest Coherent 10kW ARM FL laser features increased center beam power with a removable 50/200 micron process fiber. This new product variant enables the deepest copper welding ever achieved by Coherent. This innovative design combines:

- 5kW high-power 50-micron center beam: Increasing the center beam power from 2.5 kW to 5 kW significantly improves penetration depth and welding speed. Thanks to Coherent's extensive experience in optimizing ring and center fiber laser technology, this new configuration is achieved while maintaining the highest weld quality expected from ARM technology.

- Beam delivery flexibility: A high-power center beam with a removable process fiber enables welding in a mass production environment with either fixed optics or a highly productive scanning head such as HighMotion 2D (welds under 6 mm).

Using Coherent's deep copper laser welding technology, manufacturers can produce stronger, lighter, and more efficient electric vehicles for a sustainable future.