Laser marking is literally everywhere - from the keys on laptops and car dashboards to the milk carton in the fridge, the logo on golf clubs to the instruments used by surgeons. In fact, marking is one of the biggest uses of lasers today because it has many advantages over other methods such as printing. As an example, lasers can easily create a permanent mark on most materials that will not peel or smudge, even with frequent handling.

Two types of laser marking

If laser marking really is everywhere, does that mean that anything can be marked with a laser? Well, almost yes. Even diamond, the hardest known material, can be marked with our lasers. And why is laser marking so important? Laser marking, for example, creates a small but indelible mark on a stone that doesn't change its appearance, but clearly identifies it and helps reduce fraud.

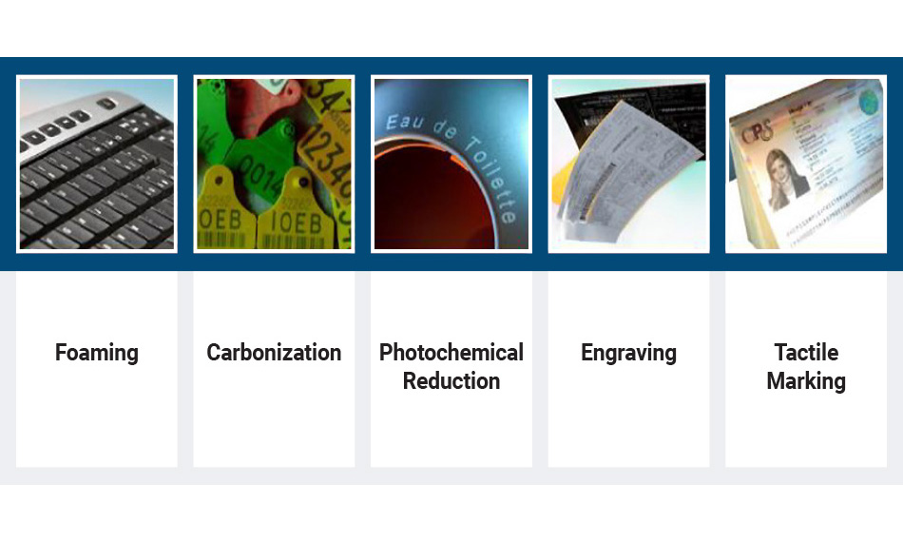

If lasers don't add any colour or other material to an object, how can they actually mark something? It really depends on the object - what it is made of, what the mark is supposed to look like and how it will be used. In the broadest sense, however, all laser marking basically falls into just two categories:

- Marks that create a colour or contrast change to the surface

- Marks that involve the removal or alteration of surface texture

Material removal is really just engraving, which is familiar to almost everyone and fairly easy to understand. In this case, the laser merely burns or vaporizes a portion of the material where it hits the surface. Making a mark, then, involves moving (or scanning) the beam to engrave the desired letters, numbers, barcode or graphics. Sometimes the grooves created are then filled with a material that contrasts with the colour of the original surface to make them more visible, just like traditional engraving.

Marking without disturbing the surface

There are quite a few different ways to use a laser to make a colour change, depending on the material being marked. In almost all cases, however, the idea is to create a high-contrast mark without damaging the surface, which can then be easily read (by person or machine).

For white and transparent plastics, the laser can create a dark mark by heating (and carbonising) the material. On the other hand, coloured and dark plastics can be photocoloured. This means that the plastic can fade or become lighter in colour when exposed to the laser. And the same laser bleaching method is used to create almost all popular wear and damage patterns on jeans. Wood is also a material that can be easily charred with lasers, such as souvenirs, creating logos when making signs and bulletin boards, etc.

Another popular method of marking plastic is called foaming. It is actually a kind of combination of engraving and colour change. It is used a lot to produce white or light-coloured marks on dark-coloured plastics such as computer keys. In foaming, the laser brings a small amount of material to a boil and it cools down into a hard foam. Similarly, 'tactile marking' creates raised patterns that can be felt by anyone, including the visually impaired.

Laser black marking - the latest technique for marking metals

Lasers can also perform colour changes on metals. In fact, a relatively new method called "Laser Black Marking" is proving very popular for reusable medical devices such as surgical instruments and endoscopes. In this case, an ultrashort pulsed (USP) laser causes microscopic structural changes on the surface of the metal. This altered metal surface then does not reflect light and appears black - even though the material is not burnt and there is no structure visible on the mark that can be palpated. Manufacturers of some premium electronic equipment use the same method to mark logos and serial numbers on their products in a way that cannot be easily forged or altered.

Customizing the marking system to your application

The specific laser used for a particular marking job depends on the material, the desired appearance of the mark, and of course, economics - how much the manufacturer is willing to spend to produce it. There are many different methods used and specific types of lasers that are best suited for each. This is why Coherent offers such a wide selection of laser marking systems.

This was just a brief introduction to how you can mark things with a laser, and we really only scratched the surface (as opposed to laser marking, which doesn't damage the surface). But as you look around your desk, office and home, ask yourself - how many laser markers do you see that you didn't even notice before?

For more information on Coherent ExactMark and other laser marking machines, click here.

Source: www.coherent.com