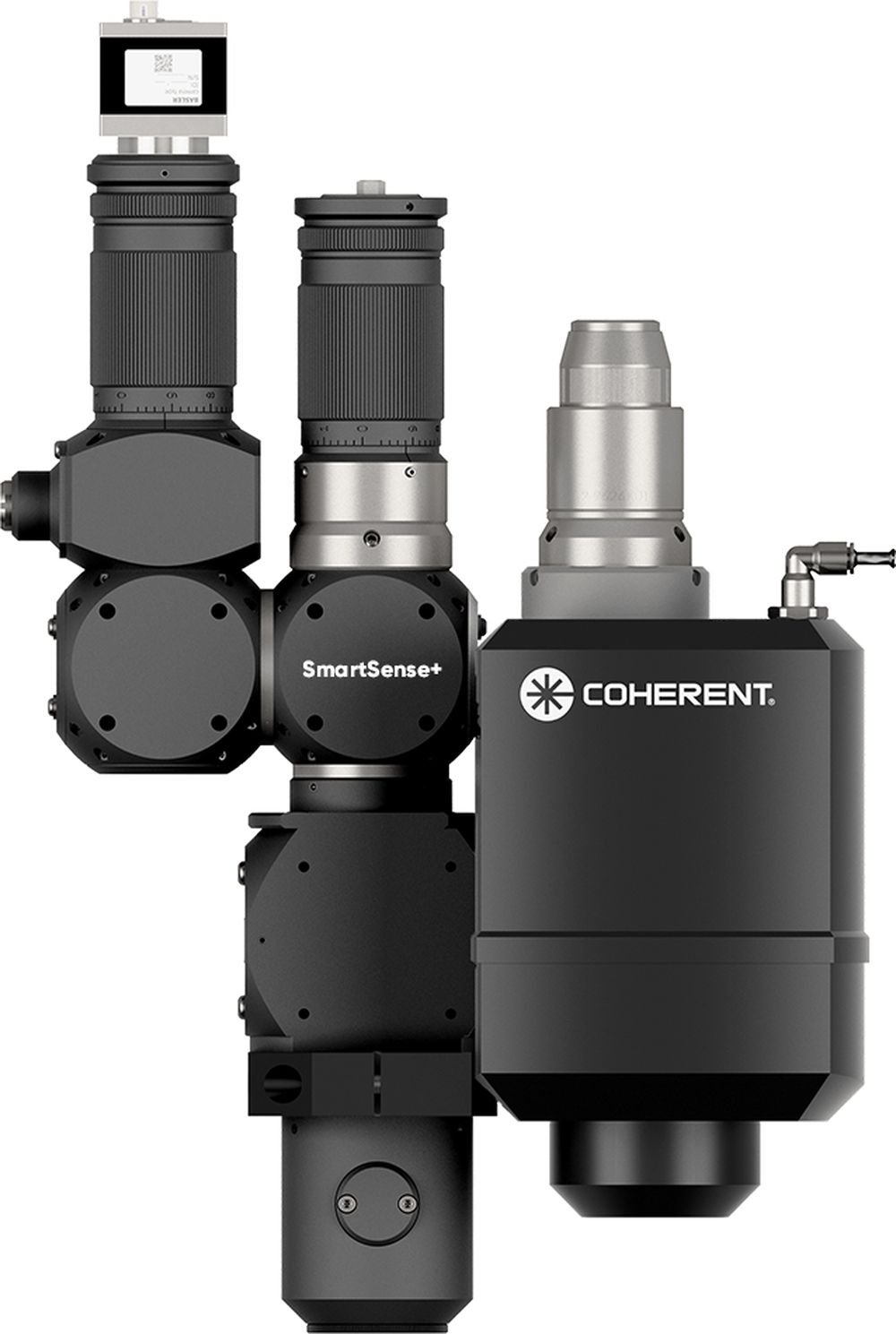

Modern weld quality monitoring technologies play a key role in optimizing laser processes such as welding, cutting, and surface treatment. Coherent's SmartSense+ system provides a cutting-edge solution that combines advanced hardware, data analysis, and artificial intelligence to ensure high weld quality and consistent results.

How SmartSense+ works

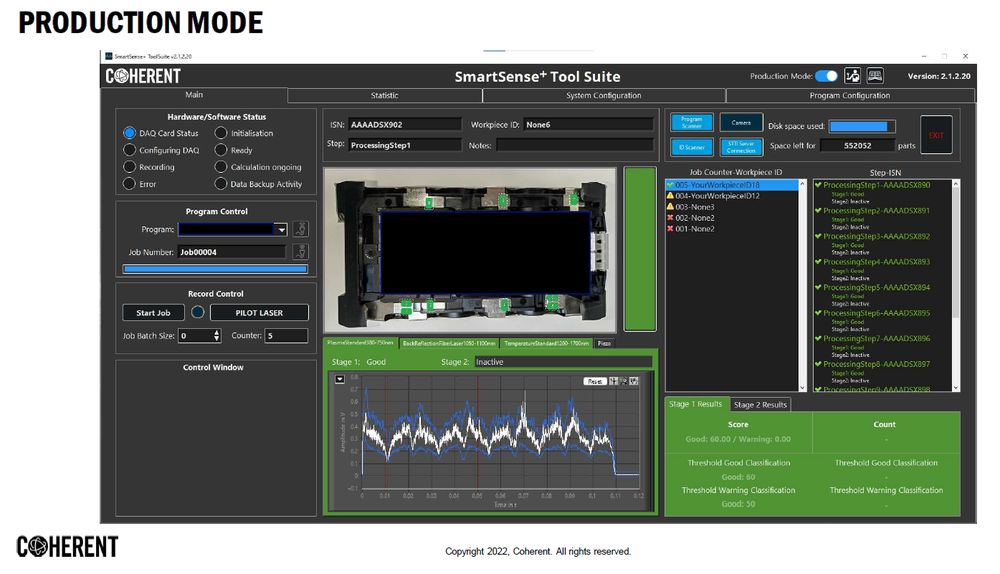

SmartSense+ is an opto-mechanical device that integrates optical detectors and (optionally) acoustic and touch piezo sensors together with complete electronics for data recording and signal processing. The system can be easily integrated into laser systems such as ExactCut, ExactWeld, StarCut, or PowerLine.

How does it work?

- The optical system captures the reflected laser beam and radiation emitted by the process itself. The captured signals are divided according to wavelength into a visible component, laser wavelength, and near-infrared radiation (NIR) and sent to separate detectors for evaluation.

- The acoustic piezo sensor captures signals that may indicate problems, such as cracks forming during or after the welding process.

Main monitoring options

Optical signals:

- Visible light intensity (so-called plasma).

- Laser backscatter, which indicates energy absorption by the material.

- Thermal radiation of the processed material (temperature).

Acoustic signals:

- Sound emissions in the air.

- Contact signals from the welding process.

Analysis methods

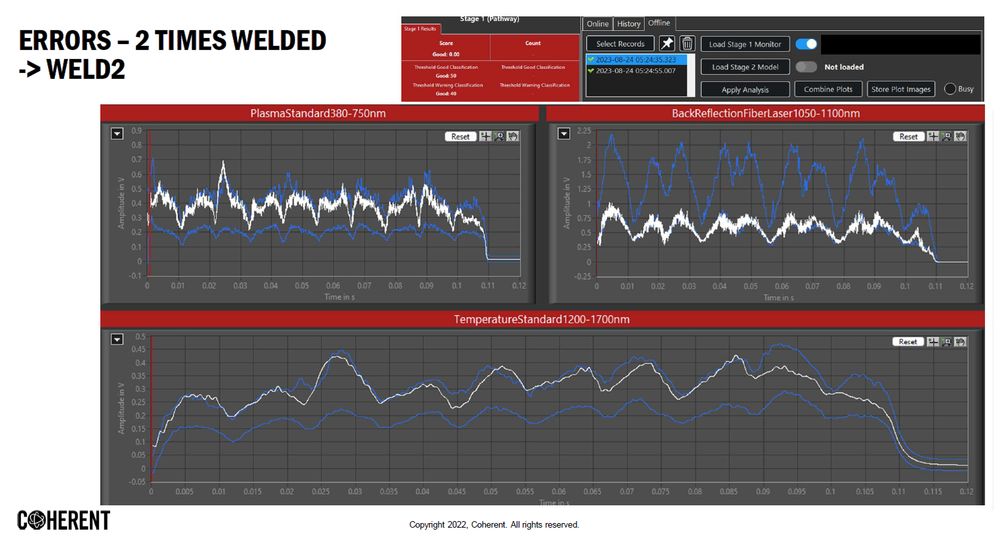

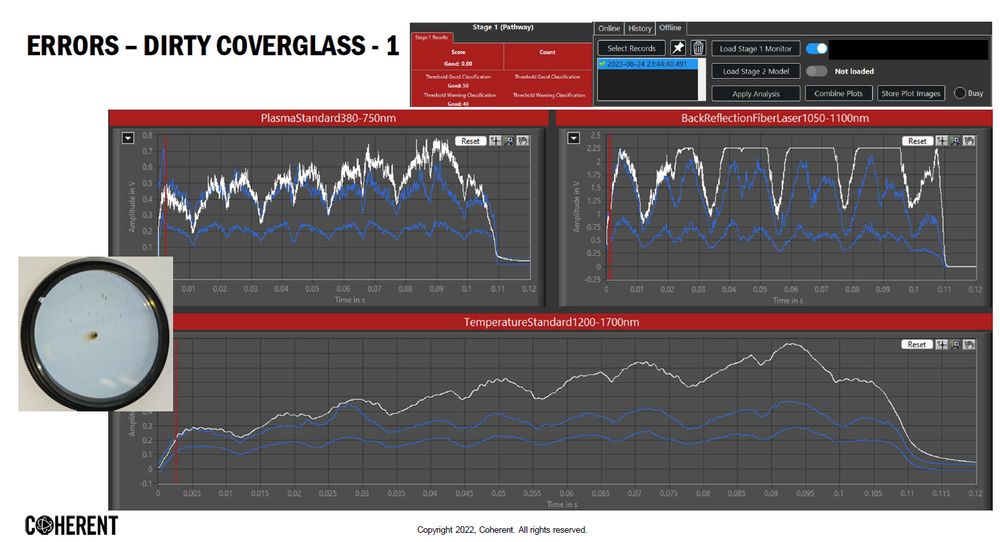

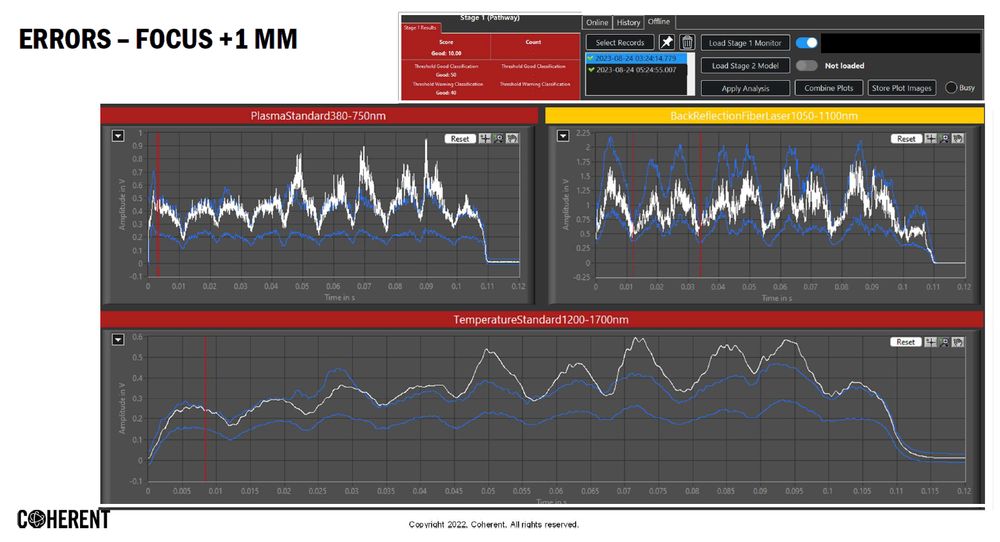

The combination of all optical and acoustic signals from the process then provides a detailed "fingerprint" not only of the entire process, but also of the subsequent cooling phase. The system offers two main methods of analysis:

-

Determination of the process path:

- Several tests are performed to determine the signal limits for a correct process.

- If the process exceeds these limits, it is immediately flagged as faulty.

-

Machine learning and artificial intelligence:

-

The system analyzes a set of tests, learns to distinguish between correct and faulty processes, and can identify the causes of errors.

-

The acquired data is subjected to analysis, which includes evaluating the upper and lower limits of signals according to sample processes and implementing machine learning algorithms for defect detection and optimization. This provides a detailed "fingerprint" of the entire process and determines whether it meets the required standard. If the process exceeds the limits, it is immediately flagged as faulty.

Using SmartSense+

What information can SmartSense+ provide you based on all this data? Quite a lot, actually. For example, during the welding process, you can obtain information about:

-

about the process

- whether the welding process actually took place or not

- information about the width of the horizontal and vertical gap between parts

- information about changes in the flow of process and shielding gas

-

about the operating conditions of the laser

- information about changes in power density

- information about fluctuations in laser power

- information about changes in the focal position and distance of the laser

-

weld quality assessment:

-

surface defects in the weld, such as contamination and scratches

-

holes, cavities, and microcracks in the weld

-

Insufficient penetration or undercutting

-

"Bumpiness" of the weld

-

Spatter of molten metal

-

Typical welding problems detected by SmartSense+

Typical welding problems that SmatSense+ reliably detects include issues that are unavoidable in any welding line. These include, in particular

- Incorrect welding materials

- Laser power too low/too high

- Undesirable gap between welded parts (horizontal and vertical)

- Contamination of the part surface

- Processing outside the laser focus

- No or insufficient protective gas

- Contaminated cover glass of the laser optics

In addition to providing high-quality process data, SmartSense+ is also versatile. The use of high data acquisition rates allows it to work with both continuous wave (CW) and pulsed lasers. It can also accurately measure industrial lasers with high and lower power levels. And while monitoring processes of this type has traditionally been used only in laser welding, the information provided by the SmartSense+ system is also useful for cutting, marking, engraving, and even cleaning applications.

Advantages of SmartSense+

- Fast response: The system collects data in real time and allows for simultaneous analysis.

- Flexibility: Suitable for both continuous and pulsed lasers.

- Reliability: Accurate identification of defects such as misaligned materials, material contamination, or laser focus issues.

- Statistics: The system provides an overview of how many good and bad parts have been produced, facilitating quality control.