Recently, the use of lasers has been increasing in a wide range of fields, including home workshops and various hobby activities. However, along with the availability of cheap, powerful Asian-made lasers comes the need for workplace safety. Users sometimes unknowingly put themselves at risk of irreversible damage to their health.

Good eye protection is an integral part of safe working with lasers and laser equipment in general.

Although the user is generally not directly exposed to the laser radiation, reflections from various surfaces can be dangerous, reaching up to 90% of the incident power in the case of highly reflective materials. The human eye has a natural protection in the form of the so-called "blink reflex" - if the eye is strongly irradiated, it closes automatically. However, this reflex does not prevent permanent damage if the incident radiation power is high (> 1mW) or if the light is outside the visible region (e.g. infrared lasers). In this case, the use of protective goggles, shields, windows, etc., comes into play.

The choice of suitable protection depends on the parameters of the laser used, such as wavelength, power, beam diameter or working mode (pulsed/continuous). All protective equipment must comply with the European standard known as EN 207 and 208. Only products that meet these standards can therefore be designated as certified.

In the OptiXs laboratory, we tested the meaning of certification in experiments with a low-cost infrared fibre marking laser with a maximum output power of 20 W. The output power was measured with a high-quality calibrated light power meter. We compared what protection 3 types of goggles were able to provide, which should theoretically be suitable for the laser wavelength of 1064 nm used. In two cases, these were glasses that absorbed the radiation (absorptive) and in one case they were glasses that reflected the radiation (reflective). However, only one of them - the Univet glasses sold by us - was certified. An overview of the glasses tested is also shown in the table below:

Table 1: Overview of the protective eyewear tested

For the goggles, we tested two basic properties - transmission (transmittance) for the wavelength used at short (~1 s) irradiance and behaviour at longer (20 s) irradiance. In doing so, we simulated two common ways in which damage to the wearer's eye can occur - i.e., a brief flash when handling the laser device and prolonged exposure to light that is not protected against by the blink reflex.

The first test showed a very striking fact, namely that the goggles supplied directly with the marking laser (i.e. non-certified absorption goggles) transmit about 35% of the incident power at 1064 nm! Certified absorption and non-certified reflective glasses, on the other hand, did not transmit any detectable power (within the accuracy of the measurements).

More detailed information on the properties of the glasses was then provided by measurements at longer irradiance. Here, we made measurements for multiple laser power levels from 1 to 20 W. The amount of transmitted radiation over a full 20 seconds was recorded by a power detector placed under the goggles, while observing how the goggle material reacted to the laser - see the photographs of the test setup in Fig. 1 (Experimental setup for testing goggles).

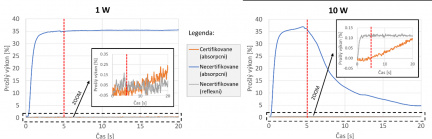

The results of our measurements are illustrated in the graphs in Fig.2, where the measured values at incident power of 1 and 10 W are compared. Let us first look at the behavior of the uncertified absorption goggles (plotted in blue in Fig.2). The measurement at 1 W confirms our previous conclusion that these glasses transmit about 35% of the incident laser radiation. Apparently due to this relatively low absorption, the glasses showed no signs of damage even after 20 s. This was not the case at 10 times the power, when the glasses started to be damaged after about 5 s. Paradoxically, the increased scattering on the molten glass reduced the amount of transmitted power to about 5%, but even this is still an unacceptably high value.

In contrast, both certified absorptive and non-certified reflective glasses released a seemingly negligible amount of power, which compared to the non-certified absorptive glasses looks like a constant zero in the graphs in Fig. 2. However, a closer look at these data (inset graphs in black boxes) reveals some differences here as well. The non-certified reflective glasses transmitted virtually no radiation at lower power, but at higher power there was a measurable transmission of about 0.12% from the first moments. At an input power of 10 W, this corresponds to a transmitted power of about 12 mW, well above the safe limit. All this without any visible signs of damage. Therefore, even these glasses cannot be recommended for use with a marking laser.

The best performers in our test were the certified Univet absorption glasses. Regardless of the power used, they lasted for the first 5 seconds without measurably transmitted radiation. However, due to the high absorption, these goggles suffered visible damage almost immediately, which also caused a slightly increased transmittance of the incident radiation after 5 s (roughly at the level of non-certified reflective goggles). The observed initial period of 5 s is not accidental here - this is exactly the time for which, according to the standards mentioned above, the goggles must withstand the action of a continuously operating laser (which for the purposes of our experiments can be considered to be the recording laser we used). This is why the 5 s limit is highlighted by the dashed red line in the graphs in Fig. 2.

Fig. 2: Time evolution of the transmitted power through the three types of goggles tested for two levels of input power of the marking laser (1 and 10 W).

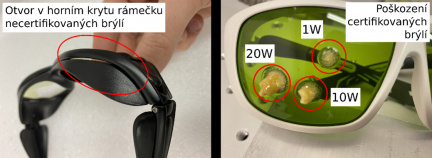

The conclusion from our test is therefore quite clear - only properly certified goggles provide safe protection. In fact, only these withstood the laser radiation for the prescribed time, which gives the wearer enough time to move out of the path of the incident beam. Visible damage on the surface of the glasses from the first moments even at low power gives the user sufficient warning - see also the photographs of the affected areas on the certified glasses in Fig.3.

None of the non-certified glasses met the prescribed standards. This can be particularly dangerous for glasses supplied directly with the marking laser. Moreover, with safety glasses, it is not only the glasses themselves that are important, but also the design of the frames, which must be at least as resistant as the glasses and should also protect against laser impact at high angles. As shown in Fig.3, non-certified reflective glasses do not have this protection.

Fig. 3: Illustration of poor frame design of non-certified reflective glasses (left), glass damage of certified glasses after 20 s of exposure to lasers set at different power levels (right).