The Transmitted Wavefront Error (TWE) is used to determine the quality of transmission optical elements in terms of their transmission properties.

In contrast to surface shape measurements, transmitted wavefront measurements include the sum of deviations due to front and back surface variations, wedging and material inhomogeneity. This metric, which tells the overall performance, offers a better understanding of the actual performance of the optics.

Although most optical components are individually tested for surface form or TWE specifications, these components are inevitably built into more complex optical assemblies with their own performance requirements. While for some applications it is possible to rely on generic component measurements and tolerances to predict final performance, for more sophisticated applications it is essential to measure the assembly to size.

TWE measurements test whether optical systems meet predetermined specifications. In addition, they are useful for reducing assembly time by actively aligning systems. In doing so, they ensure that the optical assembly matches the expected performance.

In addition to the visible region of the spectrum, we also offer other wavelengths for testing optics under conditions as close to the end application as possible.

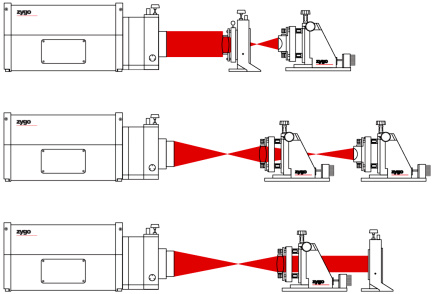

Real-time alignment of optical systems

Zygo's patented DynaPhase® data acquisition technology (available on all current Zygo interferometer models) enables real-time measurement of temporal change in optical systems and alignment of optical components. All with superior accuracy.

Watch the video for a brief demonstration

With the help of Zygo interferometers, the measurement of transmitted wavefront error (TWE) is unambiguous and reliable.