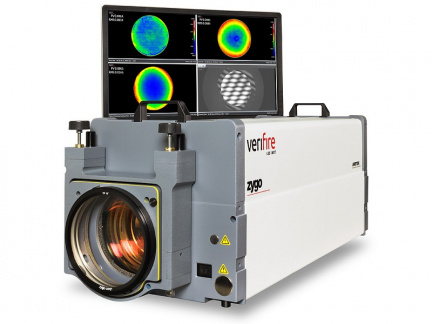

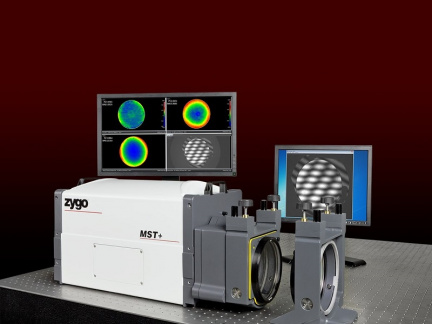

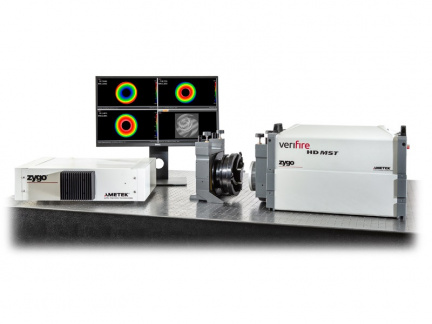

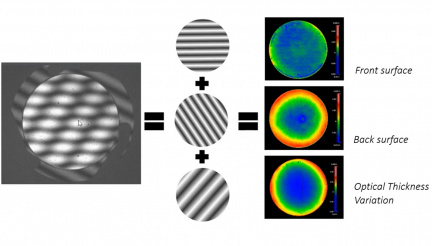

Simplify the complex - multiple surfaces create complex patterns of interference fringes. Verifire™ MST uses patented wavelength shift technology to acquire phase data from multiple surfaces simultaneously. This enables reporting of key metrics from individual surfaces of parallel glasses, transmitted wavefront, as well as precise information about individual surfaces such as total thickness variation (TTV), wedge-shapedness and even material inhomogeneity.

Verifire™ MST is designed for demanding applications such as mobile device display glasses, data storage disks and semiconductor wafers, with accurate surface and thickness variation metrology for test parts as thin as 0.5 mm.

Key features

- Simultaneous surface and wavefront characterization

- Accurate relative metrology of multiple surfaces, such as TTV and wedging

- Zygo's patented technology based on wavelength shift interferometry

- Wide range of wavelengths for different materials (633 nm to 1.55 µm)

- Wide range of lateral resolution for optimal ITF (1.2kx1.2k to 3.4kx3.4k)

- Accurate, non-contact and fast metrology of parallel surfaces

- Measurement repeatability in the nanometer range

- Unique QPSI™ technology enables reliable measurements in vibration-prone environments

- Comprehensive Zygo Mx data visualization and analysis software

- Suitable for glasses, plastics, crystals and semiconductors

- Patented Ring of Fire™ artifact reduction source