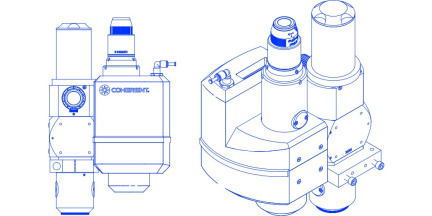

High-speed LFS/QFS process head with FLBK SC for laser scribing including beam optics, process gas nozzle and control software. Designed for grooving connecting rods of internal combustion engines before hydraulic cracking.

The only fully integrated laser taper grooving solution on the market.Output capacity is 1 piece per second.

Perform fast and highly consistent laser knurling of combustion engine cones with a fiber laser based system that can be easily integrated into the production line.

The FLBK SC system has been the global standard for taper marking in the automotive industry (for subsequent hydraulic cracking) for more than 20 years. Application-optimized fiber lasers and controlled rotating optics ensure high throughput and process consistency.