Thanks to the technological advances of recent years, it is possible to machine surfaces with ever greater precision. More than ever, high demands are being placed on the quality and accuracy of the surface texture measurement itself.

In the context of surface roughness measurement, three important factors can be identified: surface measurement, data analysis and reporting of results.

Surface measurement

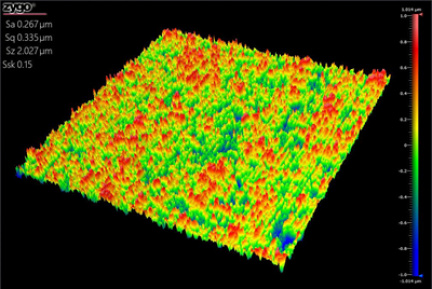

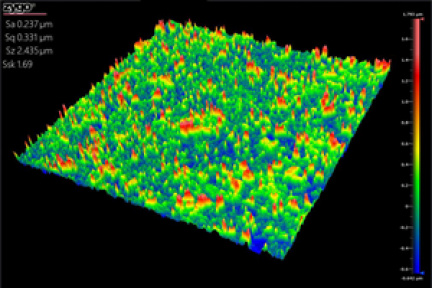

Accuracy plays a key role in surface measurement. Without high precision, it is impossible to ensure the accuracy of the roughness measurements. Zygo 's 3D optical profilers turn the collection of accurate data into a quick and easy process. In addition, with SmartSetup™ technology, you can ensure a complete measurement at the touch of a button. Everything from automatic surface detection to parameter adjustments to actual surface measurement with a single click.

Data analysis

As with any surface roughness measurement, the raw data must first be cleaned of data that is indicative of, for example, surface waviness and shape. If you want to simplify this process, Zygo 's Mx™ software is the right choice.

Report results

Historically, Ra (arithmetic mean deviation of the roughness profile) has been the main output for determining surface roughness. While this is undoubtedly an important figure, focusing on it alone would deprive us of significant results. In addition to the multi-linear extension of the linear parameter Ra to its planar alternative Sa, there are several other values that can be used to better and more accurately describe the specific properties of surface topography:

- Are you interested in the symmetry of the surface, are peaks or valleys more typical of the surface?

- Ssk(Slope of the surface under consideration)

- Are you interested in the presence of unusually large depressions or high peaks?

- Sku(Peakiness of the surface under consideration)

- Are you interested in the density of peaks?

- Sds (Peak density)

- Are you interested in surface adhesion, lubricant or surface coating?

- Sdr (Developed boundary area ratio)

- Are you interested in the rate of change of surface texture?

- Sdq (Square diameter of surface slope)

- Are the textures on the surface periodic or more random?

- Str and Sal (Longitudinal Structure Factor and Fastest decay of the length of the autocorrelation function)

These parameters and many more can be automatically evaluated in our Zygo Mx™ software.