Surface shape and texture

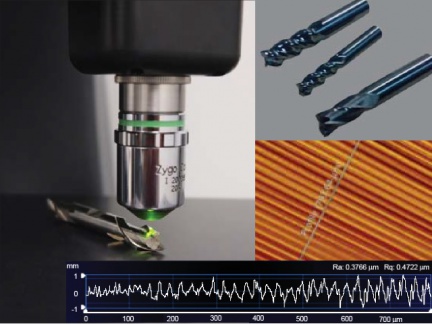

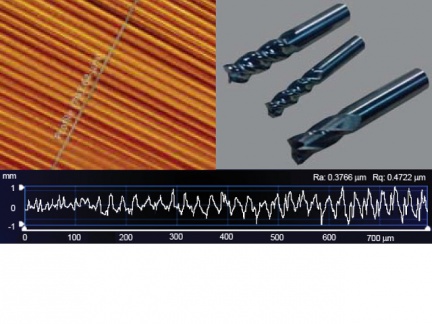

Modern manufacturing methods require the use of high-speed tooling with sophisticated shapes to machine material quickly and efficiently to produce a variety of components. Machining tools require control of the sharpening of cutting edges, the roughness of grooves, the inspection of possible cracks and breaks, but also the display of possible microstructures on the surface for a wide range of effects.

Commonly used machine vision systems can handle some of these tasks, but never all of them at the same time with sufficient reliability and resolution. However, for reliable and accurate shape and roughness measurements with high transmissivity,white-light interferometers are widely used by leading manufacturers worldwide. Already the basic Zygo - ZeGage™ range of profilometers provides an unprecedented approach to quantifying the porosity parameters of measured objects at up to sub-nanometer vertical resolution.

Thanks to the customizability of the ZeGage™ profilometer and the supplied Mx™ software, the user can simply insert the tool on the pad, press a button and obtain the required data from the surface area under investigation.

High repeatability of part measurements is key when monitoring the manufacturing process. This is key to reducing scrap and increasing tool life.

Mx™ software is fully compliant with ISO 4287/4288 (2D profile) and ISO 25178 (3D structure). The tools and controls in the Mx™ software environment are clear and easy to understand.

The sub-nanometer vertical resolution, independent of the interferometric lens used, provided by Zygo's profilometers enables accurate measurement of slope, micro-roughness and shape without the need for external vibration isolation.