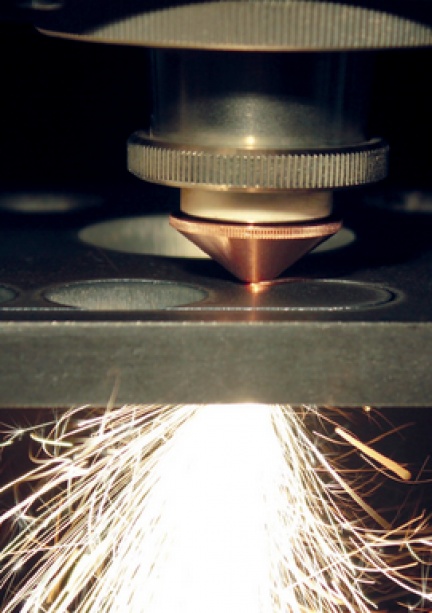

Laser cutting is an advanced industrial process with high flexibility, which is non-contact and does not cause mechanical stress on the material. In most cases, laser cutting results in finished parts that do not need further modification. Laser cutting is a very precise process with excellent dimensional stability, a very small heat affected zone and narrow cutting edges. Different technologies are used in the process depending on the type of material to be cut.

Plastics, ceramics, fibre-reinforced materials and organic materials such as leather, fabric, paper, wood and others are ideally processed using CO2 lasers. The 10.6 μm wavelength of Coherent Diamond CO2 lasers offers optimal absorption for cutting by evaporation or fusion of non-metallic materials. While the 10.6 μm wavelength of the Coherent Diamond CO2 lasers offers the possibility of cutting plastics and metallic materials, the Coherent HighLight FL series fiber lasers emit a 1 μm wavelength beam that is optimal for cutting metals, including highly reflective materials such as aluminum, copper, brass or stainless steel. Other brittle and transparent materials open up the opportunity for ultrashort pulses and UV lasers. For example, cutting glass and sapphire with internal/external contours and bevels is very effective using our high power picosecond lasers.

Thanks to the manufacturer's application laboratory, we are able to design a suitable solution for your needs and supply either the laser itself or a complete system including technology instructions.

Materials:

- Metals: iron, steel, copper, aluminum, bronze, brass, tungsten

- Polymers: plastic, rubber, acrylic (plexiglass), kevlar

- Others: paper, wood, plywood, cork, textiles, leather, glass, sapphire, etc.

Related products:

- CO and CO2 lasers

- Solid-state picosecond and femtosecond lasers

- fiber lasers

- META laser cutting systems