Increase productivity and quality in the processing of plastics and plastic components with powerful COHERENT lasers and laser systems.

Benefits of laser processing:

Easy customization

With software-controlled laser processing, you can easily and quickly change the shape of the cut-out, the content of the laser marks, the surface texture and adapt the final product to the customer's requirements.

Excellent quality

Using the right laser, you get great quality in addition to high speed and precision. This saves you time and costs for further production operations.

Consistent results

Achieve higher accuracy and fewer repairs and complaints with laser machines that deliver consistent performance and precision throughout their lifetime.

Plastic marking and serialisation

Mark each manufactured piece with a logo, lettering or unique brand that allows tracking and identification throughout its lifetime.

More about laser marking: here

For example, you can use the following systems for plastic marking and serialisation:

Plastic welding

Diode lasers weld polymers with minimal heat input, leaving a perfectly clean, undamaged surface after welding. Sensitive components such as various sensors can also be hermetically sealed using laser welding.

More about laser welding of plastics: here

For example, the following systems can be used for welding plastics:

Plastic cutting

CO₂ laser cutting of plastics ensures clean, straight edges without burrs and the need for polishing. High repetition rate and power stability guarantee consistent production throughout the lifetime of the laser source.

For example, the following systems can be used for cutting plastics:

Grooving and Thickening of Plastics

CO₂ lasers can also be used for grooving and thickening plastics. The laser can be used not only to create lettering and logos, but also to create functional grooving and thickening of plastics with consistent depth.

For example, the following systems can be used for grooving and thickening plastics:

Cutting glass fabrics

CO₂ lasers are a highly reliable source for cutting glass fabrics at high speed. While cutting, they simultaneously seal and bond the edges of the material to prevent fiber fraying.

For example, the following systems can be used for cutting glass fabrics:

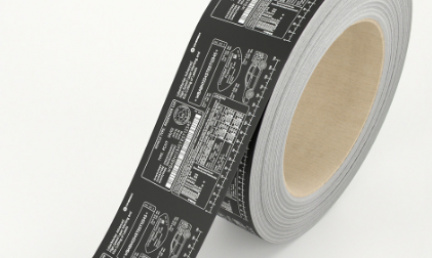

Marking plastic labels and tags

Flexible, high-performance systems that bring the benefits of non-contact, high-speed, consumable-free laser marking to more than just automotive manufacturing.

For marking plastic labels and tags, you can use systems such as these:

On-the-fly marking speed and the freedom of 3D marking

Many marking applications involve marking on a conveyor belt, during spooling or rotary motion. COHERENT lasers also enable automatic, distortion-free marking on curved and 3D formed parts used in exterior and interior applications, regardless of the shape of the part.

For example, the following systems can be used for 3D marking: